With the advancement of technology, io link devices have become an integral part of various industries. These devices enable seamless communication between sensors, actuators, and controllers in automated systems.

The Advantages of IO Link Devices

IO link devices offer numerous benefits to industrial automation processes. Firstly, they provide real-time data transmission with high accuracy and reliability. This ensures efficient monitoring and control of manufacturing operations. Additionally, IO link devices are easy to install and configure due to their standardized plug-and-play functionality.

Furthermore, these devices support bidirectional communication, allowing for remote parameterization and diagnostics. This enables quick identification and resolution of any issues that may arise during operation. Moreover, IO link devices facilitate predictive maintenance by providing valuable insights into equipment performance through continuous data collection.

The Role of Fieldbus Systems

In conjunction with IO link devices, fieldbus systems play a crucial role in industrial automation design. Fieldbus systems serve as a network infrastructure that connects multiple IO link devices within a plant or factory.

Fieldbus systems enable efficient data exchange between different components in the system while minimizing wiring requirements. They provide centralized control over distributed peripherals such as sensors and actuators by consolidating communication channels onto a single bus.

This integration simplifies system architecture while reducing costs associated with cabling and installation time. Furthermore, fieldbus systems allow for flexible expansion without disrupting existing connections or requiring extensive rewiring efforts.

Solidot Electronic Technology: A Leading Provider

Solidot Electronic Technology is at the forefront of developing innovative solutions for industrial automation utilizing IO link technology.

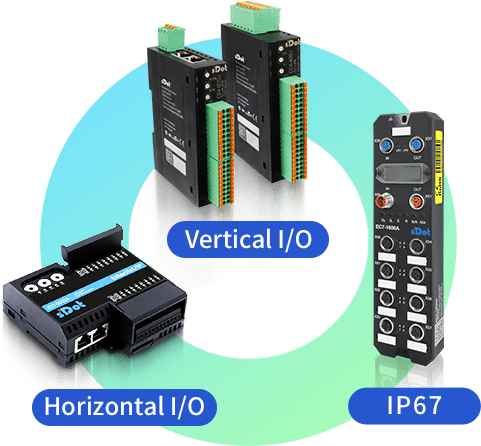

The company offers a wide range of IO link devices designed to enhance productivity and efficiency in various applications. Their products include intelligent sensors, actuators, and IO link masters that seamlessly integrate into existing automation systems.

With a focus on quality and reliability, Solidot Electronic Technology ensures their devices meet industry standards while providing advanced features such as remote parameterization, diagnostics, and predictive maintenance capabilities.

Conclusion

In conclusion, IO link devices have revolutionized industrial automation design by enabling seamless communication between sensors, actuators, and controllers. The advantages of IO link devices include real-time data transmission, easy installation and configuration, bidirectional communication for remote parameterization and diagnostics, as well as support for predictive maintenance. When combined with fieldbus systems like those offered by Solidot Electronic Technology, these devices provide an efficient network infrastructure that simplifies system architecture while enhancing productivity in various industries.