Have you ever wondered how warehouses efficiently manage their inventory and ensure timely deliveries? The answer lies in warehouse logistics automation, a game-changing technology that has transformed the supply chain industry.

The Rise of Warehouse Logistics Automation

In recent years, warehouse logistics automation has gained significant traction due to its ability to streamline operations and enhance efficiency. With automated systems such as robotic picking and sorting machines, warehouses can now handle large volumes of goods with minimal human intervention. This not only reduces labor costs but also eliminates errors caused by manual handling.

Furthermore, warehouse management software plays a crucial role in optimizing inventory control and order fulfillment processes. By leveraging advanced algorithms and real-time data analysis, these systems enable warehouses to accurately forecast demand, allocate resources effectively, and minimize stockouts or overstock situations.

Solidot Electronic Technology: A Pioneer in Warehouse Logistics Automation

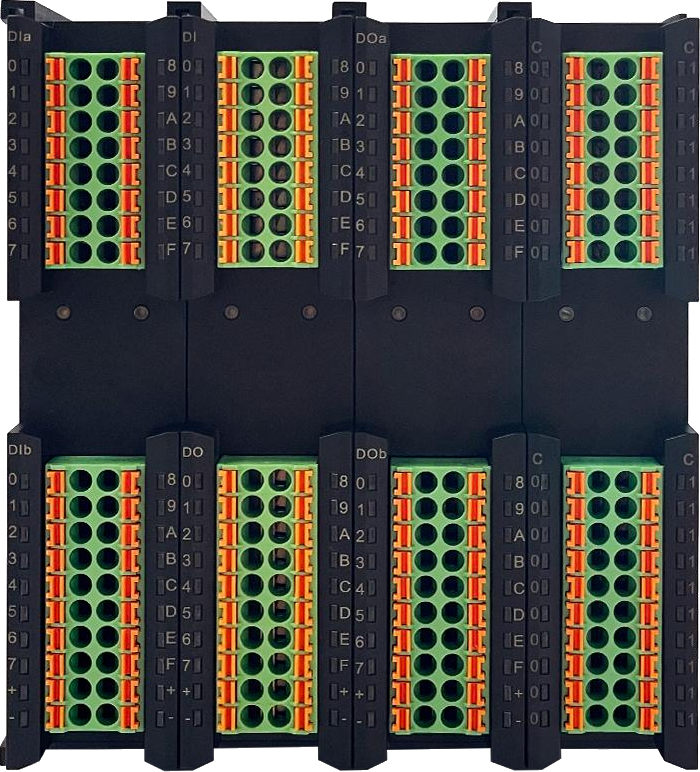

Solidot Electronic Technology is at the forefront of revolutionizing warehouse logistics through cutting-edge automation solutions. Their state-of-the-art robotic systems are designed to seamlessly integrate into existing warehouse infrastructures while significantly improving operational efficiency.

One notable product offered by Solidot is their autonomous mobile robots (AMRs), which navigate through aisles independently using advanced sensors and mapping technologies. These AMRs can perform various tasks such as picking up items from shelves or transporting them across different sections of the warehouse. By automating these repetitive tasks traditionally performed by humans, Solidot’s AMRs save time, reduce labor costs, and improve overall productivity.

The Impact of Automation in the Manufacturing Industry

Apart from revolutionizing warehousing operations, automation has also made significant strides in the manufacturing industry. Automated assembly lines equipped with robotics have become commonplace for many manufacturers worldwide.

automation in the manufacturing industry offers numerous benefits, including increased production speed, improved product quality, and enhanced worker safety. By automating repetitive and physically demanding tasks, manufacturers can achieve higher output rates while ensuring consistent product standards.

Moreover, automation enables manufacturers to respond quickly to changing market demands. With flexible production lines that can be easily reconfigured or adapted for different products, companies gain a competitive edge by reducing time-to-market and meeting customer expectations more efficiently.

The Future of Warehouse Logistics Automation

As technology continues to advance at an unprecedented pace, warehouse logistics automation is poised to play an even more significant role in the supply chain ecosystem. From autonomous drones for inventory management to artificial intelligence-powered predictive analytics systems for demand forecasting, the possibilities are endless.

In conclusion, warehouse logistics automation has revolutionized the supply chain industry by streamlining operations and improving efficiency. Companies like Solidot Electronic Technology have been instrumental in developing cutting-edge solutions that optimize warehousing processes. Furthermore, automation’s impact extends beyond warehouses into the manufacturing sector where it enhances productivity and agility. As we look ahead into the future of supply chain management, embracing these technological advancements will undoubtedly lead to greater success and competitiveness in a rapidly evolving global marketplace.