Are you tired of traditional molding methods that just don’t cut it anymore? Well, let me introduce you to the world of LSR molding – a revolutionary process that will blow your mind!

Click to find more about what is lsr molding.

The Marvels of LSR Molding

LSR stands for Liquid Silicone Rubber, and LSR molding is a technique used to create high-quality silicone products. It involves injecting liquid silicone rubber into a mold cavity and allowing it to cure into its final form. This process offers numerous advantages over traditional molding methods.

Firstly, LSR molding allows for intricate designs with precise details. The liquid nature of the material enables it to flow effortlessly into even the tiniest crevices of the mold, resulting in flawless finished products.

In addition, LSR molded parts exhibit exceptional durability and flexibility. They can withstand extreme temperatures without losing their shape or properties, making them ideal for applications in industries such as automotive, medical devices, and electronics.

Furthermore, LSR materials are biocompatible and hypoallergenic. This means they are safe for use in medical implants or any other application where contact with human skin or body fluids is involved.

The JVTECH Advantage

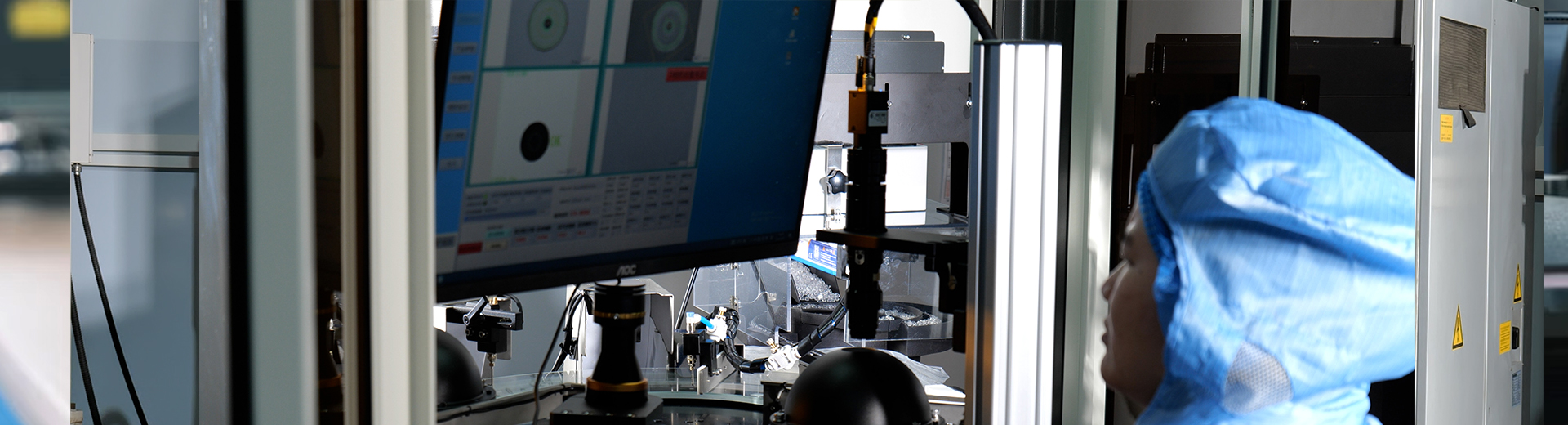

If you’re looking for top-notch quality in your LSR molded products, look no further than JVTECH! With years of experience under their belt, this company has mastered the art of precision manufacturing using advanced technologies.

JVTECH employs state-of-the-art machinery and equipment to ensure consistent production results every time. Their team consists of highly skilled engineers who meticulously monitor each step of the manufacturing process to guarantee superior quality control.

Moreover, JVTECH understands that customization is key. They work closely with their clients to develop tailored solutions that meet specific requirements. Whether it’s a unique design or a particular material property, JVTECH has got you covered.

The LSR Injection Molding Process

LSR injection molding involves several key steps. First, the liquid silicone rubber is mixed with catalysts and additives to achieve the desired properties. Then, the mixture is injected into a mold cavity using high-pressure equipment.

Once inside the mold, the LSR undergoes curing through heat or UV light exposure. This solidifies the material and allows it to take on its final shape. After cooling down, the molded part is ejected from the mold for further processing or assembly.

This process offers excellent efficiency and precision due to its automated nature. It enables fast production cycles while maintaining consistent quality throughout each batch of products.

Click lsr injection molding process.

In Conclusion

In conclusion, LSR molding is an innovative technique that revolutionizes traditional manufacturing methods. Its ability to create intricate designs, durability in extreme conditions, biocompatibility, and customization options make it highly sought after in various industries.

If you’re looking for top-quality LSR molded products that meet your specific needs, JVTECH should be your go-to choice! With their expertise and commitment to excellence, they will surely exceed your expectations every time!